|

|

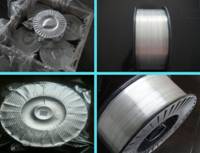

Quality Magnesium Wires Quality Magnesium Wires

|

|

|

|

|

☆ White Surface, Vacuum bag packaging |

|

☆Spooling, Vacuum bag packaging |

|

| |

1. Magnesium Welding Wires |

The surface of BECKEN’s Magnesium filler metals is white. We pack magnesium welding wires with vacuum bags to prevent magnesium welding wires from contamination and oxidation in the air. We have a smooth finish that is free from slivers, depressions, scratches, scale, seams, laps, and foreign matter that would adversely affect the welding characteristics, the operation of welding equipment, or the properties of the weld metal.

1.1 Chemical Composition of the Magnesium welding wires

Chemical Composition Requirements of AWS A5.19 as follows:

AWS Classification |

Weight Percent Max |

Mg |

Al |

Be |

Mn |

Zn |

Cu |

Fe |

Ni |

Si |

Other

Elements,

Total |

ER AZ61A

R AZ61A |

Bal |

5.8-7.2 |

0.0002-0.0008 |

0.15-0.5 |

0.40-1.5 |

0.05 |

0.005 |

0.005 |

0.05 |

0.03 |

ER AZ92A

R AZ92A |

Bal |

8.3-9.7 |

0.0002-0.0008 |

0.15-0.5 |

1.7-2.3 |

0.05 |

0.005 |

0.005 |

0.05 |

0.03 |

1.2Applicationsand Unique Character

|

BECKEN Magnesium wires are widely used in optical instruments, aerospace, spaceflight, auto parts welding, civilian magnesium products and crafts. We have the three advantages:

A. Silver Shiny Clean- Our wires are very clean, silver shining. The competitors are some dull.

B. Fine welding performance- Our wires have good straightness and high specific strength.

C. Lowest Price in the world- Unique technical process lower cost for wire production. |

| 1.3 Typical Size and Packing |

Rods: 0.047", 0.063", 0.0.079" and 0.197" in diameter, 11.82", 19.7", 36” and 39.4" in length, packed in 2 lbs or 1 kg/ plastic tube

Wires: 0.047", 0.063", 0.0.079" and 0.197" in diameter, packed in 9 lbs or 4 kg / spool |

|

| Note: Other specifications can be available as per customer's requirements. |

| |

|

|