|

|

| Unique Ferro-alloy Powders for Plasama Welding Hardfacing |

|

|

| 1. Description |

|

After PTA Plasma arc Welding Hardfacing, the feature of coating is charactered by superior wear resistance, good corrosion resistance and excellent metallurgical bonding.

Type |

Fe |

Cr |

Ni |

Si |

B |

Ti |

C |

Mn |

Mo + Cu + Co |

W + V |

La + Ce + Yt |

SP4/SP2 |

Balance |

15-45% |

0-15% |

0.04-5.5% |

2-12% |

0.01-30% |

0.5-8% |

0.01-5% |

0-15% |

0-15% |

0-5% |

Ni50 |

≤5% |

12% |

Balance |

3% |

3% |

|

0.5% |

|

|

|

|

Ni60 |

≤5% |

12% |

Balance |

3% |

3% |

|

0.9% |

|

|

|

|

|

Properties |

Full Density |

Cost |

Size,um |

Application |

Heat Input |

Wear Resistance |

Corrosion Resistance |

Replacing |

SP4 |

7.0-9.0 |

Very Economic |

45-150 |

PTA |

A |

AAA |

A+ |

HRC55-65 and Corrosion Resist |

Ni60 |

8.1 |

Economic |

45-150 |

PTA |

A |

AAA+ |

AA+ |

|

SP2 |

7.0-9.0 |

Very Economic |

45-150 |

PTA |

A |

AA |

A+ |

HRC35-55 and Corrosion Resist |

Ni50 |

8.1 |

Economic |

45-150 |

PTA |

A |

AA |

AA+ |

|

|

| 2. Unique Ferro-alloy for PTA Plasma Welding Hardfacing |

|

|

Low heat input is preference for better deposit performance.

Unique Powder SP4

Our SP4 is super hard iron-based alloy powders. The hardness can reach HRC62-65. Typical applications as follows:

|

|

|

PTA Clad Conical Mining Bit |

PTA Clad Cutter Tooth |

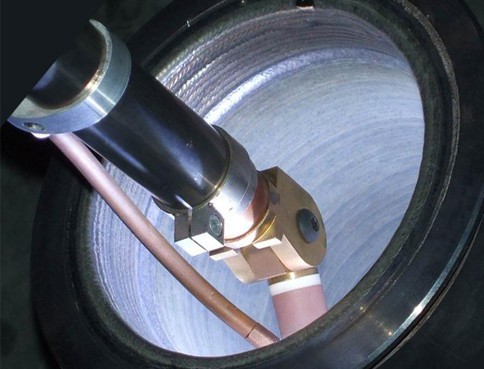

PTA Clad Wear Pipe / Tube |

|

|

|

PTA Clad Screw Conveyor |

Clad and Machined Refractory Brick Mold |

PTA Clad Light Wear Plate |

Unique powder SP2

Our SP2 is hard and sometough iron-based alloy powders. The hardness can be HRC35-55. Typical applications as follows:

|

|

|

PTA Clad Oil Hard Band |

PTA Clad Hydraulic Turbine |

PTA Clad Heavy Piston |

|

|

|

Clad for Mold Rebuild |

PTA Clad Valve Seat Inner |

Clad Valve Seal |

| 4. Package |

|

Standard packaging is by pail with polyethylene liner per 50 kg or by plastic bottle per 5 kg. |

|

| |

|