|

|

Stainless Steel Powders

for Additive Manufacturing or 3D Printing |

|

|

|

|

| 1.Chemical and Physical Properties |

AMT Type |

Weight Percent, Max |

Cr |

Ni |

C |

Mn |

Si |

S |

P |

Cu |

Nb |

Mo |

Fe |

BECKEN 316L |

16-18 |

10-14 |

≤0.030 |

≤2.00 |

≤1.00 |

≤0.03 |

≤0.045 |

— |

— |

2.0-3.0 |

Bal |

BECKEN 17-4PH |

15.0-17.5 |

3-5 |

≤0.070 |

≤1.00 |

≤1.00 |

≤0.03 |

≤0.040 |

3-5 |

0.15-0.45 |

— |

Bal |

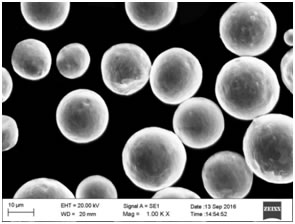

2 Characteristics of BECKEN Stainless Steel Powders

|

BECKEN Stainless steel powders have good sphericity and fluidity. Besides it has very low Porosity. The content of oxygen and other impurities are also very low. In addition, the range of Particle size can be selected. In addition, BECKEN Stainless steel powders have advantages of strength, hardness and corrosion resistance. |

| 3 Applications of BECKEN Stainless Steel Powders |

BECKEN Stainless steel powders are widely used in aviation engine components, gas turbine and the structure of chemical processing. BECKEN Stainless steel powders are typically used for SLS. This manufacturing method SLS results in rough surface, so it usually needs follow-up processing such as polishing. |

|