|

|

|

| 1. Titanium and Titanium Alloys Spherical Powders |

| 1.1 Physical and Chemical Properties: |

| BECKEN is specialized manufacturing spherical titanium powders which can be used in additive manufacturing or 3D printing and thermal spraying. |

Ti &

Ti -alloys |

Powder Type |

Particle Size,um |

Density, g/cm3 |

Flow velocity, s/50g |

Tap |

Apparent |

CPTi |

45-250um |

≥2.8 |

≥2.6 |

≤25 |

TC4 |

45-250um |

≥2.8 |

≥2.6 |

≤25 |

|

Ti &

Ti -alloys |

Types |

Chemical Composition (wt %) |

Ti |

Al |

V |

Fe |

H |

O |

N |

Others |

CPTi |

Bal |

≤0.01 |

- |

≤0.30 |

≤0.015 |

≤0.20 |

≤0.05 |

≤0.40 |

TC4 |

Bal |

5.5-6.75 |

3.50-4.50 |

≤0.30 |

≤0.015 |

≤0.20 |

≤0.05 |

≤0.40 |

|

| 1.2 Characteristics of BECKEN Titanium Powders |

Our powders are highly spherical with an excellent flowability. There are few satellite powders and porosity. The oxygen and other contaminants are very low. In addition, the particle size distribution is tailorable. |

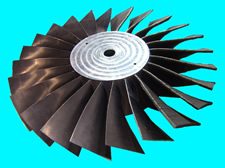

| 1.3 Applications of BECKEN Titanium Powders |

The BECKEN titanium powders have led to a wide and diversified range of successful applications in airplane structure parts, engine parts, aircraft accessories, engine control unit etc. |